Get a Free WorkTrek Demo

Let’s current you methods WorkTrek could make it easier to optimize your maintenance operation.

Try freed from cost

The maintenance enterprise is current course of a significant transformation, pushed by quick technological developments, a rising emphasis on sustainability, and evolving workforce dynamics. This textual content covers the Prime 10 maintenance enterprise traits for 2025.

These changes normally are usually not almost preserving gear working; they symbolize a elementary shift within the route of strategic asset administration and industrial maintenance that optimizes effectivity, reduces costs, and minimizes environmental have an effect on.

As we switch into 2025, quite a few key maintenance enterprise traits are set to redefine the maintenance panorama.

1. Predictive Repairs and Artificial Intelligence (AI)

In 2025 AI is what every enterprise is talking about. Huge Language Fashions like ChatGPT are dominating the knowledge cycle. Nonetheless, these devices normally are usually not always worthwhile for maintenance technicians and managers, nonetheless the rise of predictive and preventive maintenance powered by artificial intelligence (AI) is transformative.

What’s efficacious and one of many transformative traits is the rise of predictive maintenance and analytics powered by artificial intelligence (AI).

The worldwide predictive maintenance market has been experiencing very important improvement and is projected to proceed rising inside the coming years.

In response to a report by IMARC Group, the market measurement reached USD 12.7 billion in 2024 and is predicted to develop to USD 80.6 billion by 2033, exhibiting a compound annual improvement price (CAGR) of twenty-two.8% from 2025 to 2033.

One different analysis by Precedence Evaluation estimates the market measurement at USD 7.24 billion in 2024, with projections to surpass USD 79.70 billion by 2034, rising at a CAGR of 27.10% between 2024 and 2034.

So how does it work?

AI-driven packages analyze enormous portions of data to forecast potential gear failures, enabling maintenance teams to take proactive measures and in the reduction of reactive maintenance.

It’s a very important shift from reactive maintenance, the place repairs are solely initiated after a failure.

- AI-driven packages can predict gear failures and alter dynamically to altering environmental circumstances and utilization patterns. This could result in lower maintenance costs.

- Digital simulations create digital environments that mirror real-world belongings, providing insights that allow teams to anticipate effectivity shifts with out bodily intervention.

- Machine finding out algorithms improve predictive accuracy by using historic and real-time data to forecast maintenance desires efficiently and improve routine maintenance duties.

- AI can analyze real-time IoT data streams, rework maintenance packages into autonomous, self-optimizing choices, and improve gear effectivity.

- AI-enabled maintenance scheduling is one rising experience that permits facilities to plan actions for the least disruptive situations, decreasing shocking downtime.

- AI-powered predictive maintenance can improve failure prediction accuracy by as a lot as 90% whereas decreasing maintenance costs by as a lot as 12%.

By leveraging AI, maintenance teams can switch from reactive to proactive strategies, minimizing downtime, decreasing restore costs, and lengthening the lifespan of essential belongings.

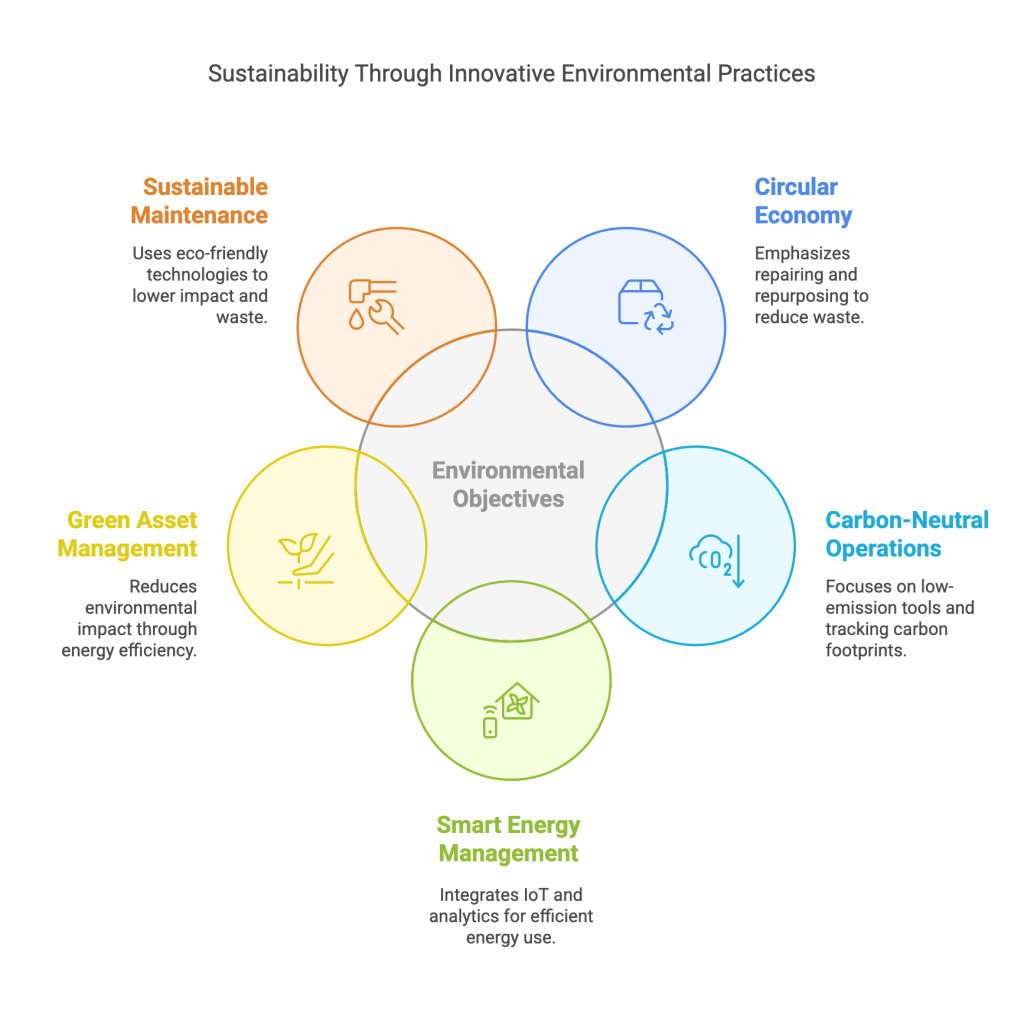

2. Sustainability as an Operational Essential

Sustainability is just not solely an organization buzzword; it has develop right into a elementary principle guiding maintenance strategies.

Repairs gear producers are increasingly providing eco-friendly choices that align with sustainability targets. Together with its environmental impacts, sustainability will in the reduction of costs and improve earnings.

In 2025 and previous, maintenance operations are anticipated to align additional rigorously with environmental targets. Integrating superior utilized sciences and sustainable practices will drive loads of this alignment.

Firms ought to implement eco-friendly protocols that in the reduction of waste and emissions and enhance operational effectivity.

One different improvement is incorporating renewable vitality sources and energy-efficient gear.

Furthermore, maintenance teams will leverage data analytics to optimize helpful useful resource utilization, guaranteeing that every facet of maintenance operations contributes to a greener and further sustainable future.

By prioritizing environmental targets, organizations can receive worth monetary financial savings, improve their mannequin reputation, and meet regulatory requirements, all whereas contributing to a extra wholesome planet.

- Spherical financial system practices are gaining traction, emphasizing repairing and repurposing elements to reduce waste.

- Carbon-neutral operations have gotten a priority, with organizations using low-emission devices and monitoring carbon footprints.

- Good vitality administration is being built-in into maintenance practices. This comprises good thermostats, good meters, IoT-based choices, and vitality analytics software program program, amongst many others.

- Inexperienced asset administration devices help in the reduction of the environmental have an effect on of belongings and operations. Firms see a median of 15% worth monetary financial savings by way of vitality effectivity enhancements.

- Sustainable maintenance protocols and eco-friendly utilized sciences in the reduction of environmental have an effect on, lower vitality consumption, and in the reduction of waste.

Specializing in sustainability reduces maintenance operations’ environmental have an effect on, achieves worth monetary financial savings, and enhances their mannequin reputation as a accountable group.

3. AI Brokers – The Future

Just like Huge Language Fashions (LLMs) like ChapGPT have dominated the previous couple of years, 2025 could be the start and improvement of AI Brokers.

Think about an AI agent as a digital assistant that will understand, research, and take movement to help with explicit duties.

Like a human assistant, an AI agent can observe what’s happening, make selections based on what it sees, and take helpful actions.

The essential factor distinction is that AI brokers can course of giant portions of data faster than individuals and work 24/7 with out getting drained.

Occasion of AI Brokers for Repairs Duties

Take into consideration you’re accountable for sustaining gear in a producing plant. Proper right here’s how an AI agent could help:

With out an AI agent, you might stroll throughout the manufacturing facility floor every morning, checking each machine, listening for unusual sounds, and maintenance data to resolve what desires consideration.

You rely in your experience to catch points, nonetheless you probably can’t be everywhere concurrently, and some factors might slip by way of.

AI Brokers Educated Assistant

With an AI agent, it’s like having a extraordinarily expert assistant who certainly not sleeps. The agent consistently screens all your gear by way of sensors, gathering data about how each machine is working.

It learns what a “common” operation seems like and would possibly spot potential points sooner than they turn into extreme. When it notices one factor concerning, it might probably warn you immediately and counsel what could possibly be incorrect based on patterns found from 1000’s of comparable circumstances.

The precise vitality comes from how AI brokers could assist in a number of strategies:

- Understanding Language: They will be taught maintenance manuals, work orders, and technical paperwork, then reply questions in plain English. In its place of digging by way of a complete lot of pages of documentation, you probably can merely ask, “What’s the maintenance course of for the cooling system?” and get a clear reply.

- Making Predictions: By analyzing patterns in data, AI brokers can inform you points like, “Based mostly totally on current effectivity, this bearing will seemingly need different in about three weeks.” This helps you intend maintenance sooner than gear fails.

- Finding out and Adapting: AI brokers improve as they research from experience. Within the occasion that they make a prediction that appears to be incorrect, they alter their understanding, much like individuals would research from errors.

- Providing Steering: When engaged on gear, an AI agent can data technicians by way of restore procedures, displaying each step on a cell machine or capsule, almost like having an expert mentor look over their shoulder.

Nonetheless, it’s essential to know that AI brokers aren’t meant to interchange human workers. In its place, they’re devices that make human workers extra sensible by coping with routine duties, providing helpful information, and recognizing points that could possibly be missed.

This lets people cope with additional difficult duties that require human judgment and creativity.

Think about AI brokers as workforce members who excel at monitoring, analyzing data, and providing information. They work alongside human employees who convey experience, judgment, and problem-solving experience.

Collectively, they’re going to receive larger outcomes than they could alone.

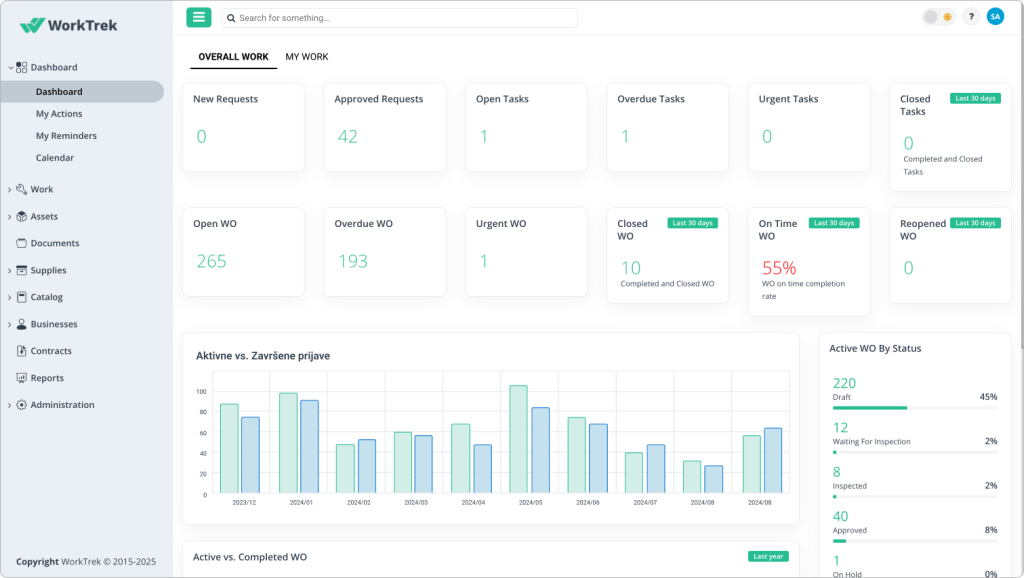

4. Unified Digital Ecosystems for Collaboration

You possibly can’t run a maintenance group with out coordination amongst all stakeholders. Many organizations have started implementing digital devices, like CMMS packages, to boost collaboration and data assortment.

In 2025, the adoption of digital devices and digital transformation will proceed and velocity up. Organizations ought to rely upon unified digital platforms that consolidate maintenance data, communication, and workflows.

- Instant data sharing grants teams quick entry to real-time effectivity metrics and course of progress.

- Constructed-in compliance administration automates packages to verify legal guidelines are met effortlessly.

- Collaborative dashboards facilitate streamlined decision-making for quick issue determination.

- CMMS (Computerized Repairs Administration Strategies), like WorkTrek and EAM (Enterprise Asset Administration), are central to this improvement. They help prepare maintenance and monitor all train in a single system.

These platforms moreover current elevated visibility into completed work, improve maintenance planning, enhance documentation, in the reduction of unplanned downtime, and gives maintenance managers elevated transparency into asset histories.

These digital ecosystems in the reduction of downtime, improve complete effectivity, and foster a unified technique to asset administration by seamlessly connecting various operations.

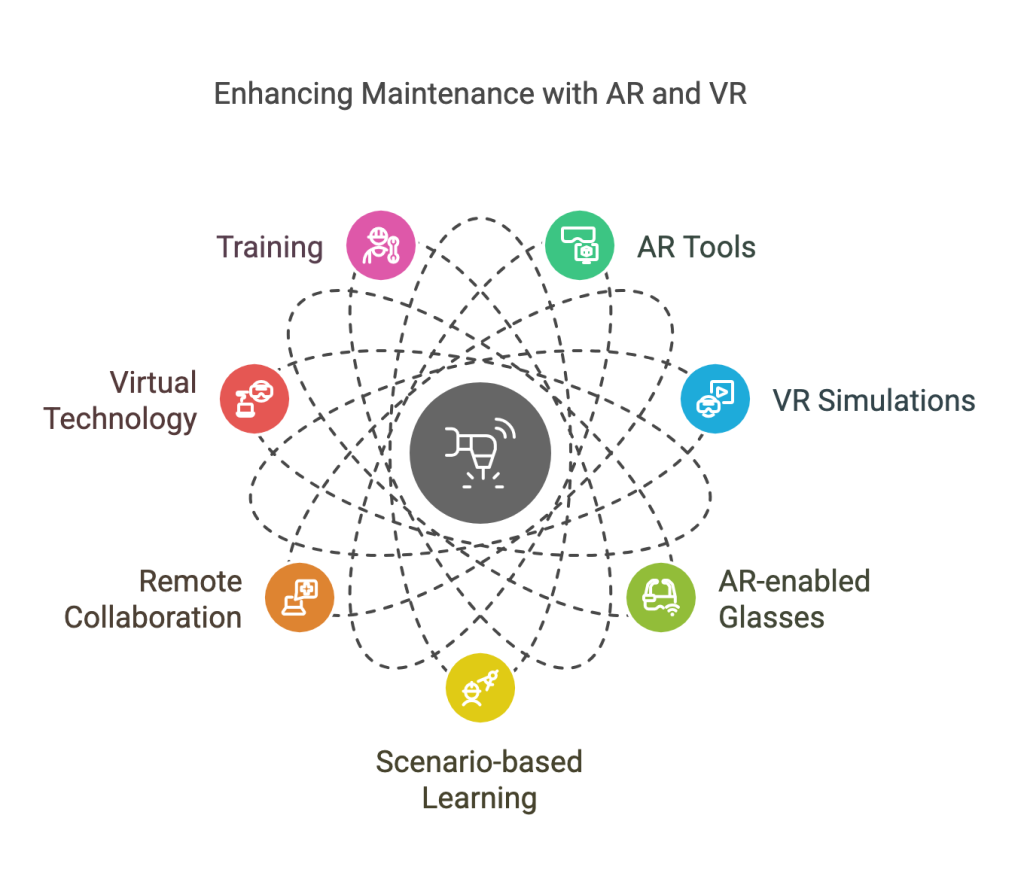

5. Immersive Repairs with Augmented Actuality (AR) and Digital Actuality (VR)

Many professionals, like fighter jet pilots and NFL soccer players, have embraced AR and VR utilized sciences.

In 2025, we anticipate immersive utilized sciences like Augmented Actuality (AR) and Digital Actuality (VR) to proceed transforming maintenance teaching and execution.

This might significantly revenue maintenance workers and improve complete operational efficiencies. These utilized sciences current new strategies to work along with gear and apply employees.

- AR devices current on-the-go overlays of equipment schematics, guiding technicians in real-time.

- VR simulations immerse maintenance teams in lifelike conditions, enabling capacity progress with out disrupting keep operations.

- AR-enabled glasses permit interactive diagnostics that highlight factors and counsel choices on-site.

- State of affairs-based finding out is facilitated by VR modules designed for superior troubleshooting and emergency response.

- Distant collaboration is significantly improved. Repairs specialists can almost assist self-discipline teams, thus decreasing journey and response situations.

- Digital experience is becoming a additional widespread methodology for diagnosing and troubleshooting, allowing offsite personnel a near “hands-on” experience.

- AR/VR may even be used to educate technicians with out the possibility of damaging exact gear.

These utilized sciences significantly enhance the accuracy and effectiveness of maintenance duties, making them indispensable in difficult and high-stakes environments.

6. Decentralized Repairs Fashions

The standard technique of centralized maintenance teams is anticipated to transition within the route of additional adaptable, decentralized buildings by 2025.

A decentralized maintenance model distributes maintenance teams and belongings all through an organization’s areas or departments.

Each workforce has the authority, expertise, and belongings to cope with maintenance duties of their explicit house with out always needing approval from a authorities. This technique brings quite a few very important advantages:

This evolution is facilitated by IoT monitoring and sophisticated communication devices, enabling distant maintenance and oversight of geographically unfold facilities.

This reduces the need for onsite devoted maintenance technicians and permits for a additional distributed model that improves effectivity.

- Faster Response Cases: When maintenance teams are positioned nearer to the gear they service, they’re going to reply additional quickly to points. In its place of prepared for a central maintenance division to dispatch any person from all through the flexibility, native teams can deal with factors immediately. That’s notably worthwhile in large facilities the place journey time between areas could also be very important.

- Larger Understanding of Native Desires: Repairs teams working persistently within the equivalent house develop deep data of their explicit gear and its quirks. They turn into accustomed to the working circumstances, widespread points, and the desires of the operators who use the gear day-to-day. This native expertise normally leads to extra sensible maintenance strategies.

- Improved Communication: When maintenance personnel work rigorously with operations teams of their house, it creates larger communication channels. Operators can merely share points or observations with maintenance employees they know and see recurrently comparatively than submitting formal requests to a distant central division.

- Additional Surroundings pleasant Helpful useful resource Use: Each house can protect its inventory of usually wished parts and devices, decreasing the time spent retrieving gives from a central location. Teams can also additional efficiently schedule maintenance actions spherical native manufacturing schedules.

This technique can lower overhead payments and improve operational flexibility, enabling organizations to manage to evolving requires swiftly.

Decentralized maintenance fashions current a additional agile technique to managing maintenance all through quite a few areas.

7. Edge Computing

In 2025, edge computing is poised to rework data processing in gear maintenance processes by decentralizing decision-making.

Think about edge computing as having a mini data center correct subsequent to your gear comparatively than sending all your data to a far-away laptop computer center.

Merely as you’d want your maintenance technicians close to the gear they protect, edge computing locations computing vitality correct the place the movement happens – on the “edge” of your neighborhood, subsequent to your gear.

Why does it matter for maintenance monitoring?

Your gear sensors purchase data about temperature, vibration, pressure, and totally different essential metrics. This data travels to a central laptop computer system, normally in a distant data center or the cloud. The system processes this information and sends once more alerts or insights.

This spherical journey takes time—usually merely seconds, nonetheless these seconds can matter when dealing with essential gear factors.

Now, proper right here’s how edge computing transforms this course of. In its place of sending all data to a distant location, edge computing devices course of information correct subsequent to your gear. These devices are like small, extremely efficient laptop techniques that will instantly analyze data and make selections. They solely ship most likely crucial information to the central system, preserving essential processing native.

Benefits to Repairs Teams

- Precise-Time Response: Edge computing can instantly detect and reply to gear points. If a machine reveals indicators of failure, the sting machine can set off an immediate shutdown or alert, doubtlessly stopping excessive damage. That’s significantly important in high-speed manufacturing, the place even a slight delay could lead to very important points.

- Improved Reliability: Since edge computing doesn’t rely upon mounted net connectivity, your monitoring packages will proceed working even when neighborhood connections are interrupted. The sting devices will proceed gathering and analyzing data and storing essential information until the connection is restored.

- Larger Info Administration: Industrial gear can generate enormous portions of data—extra of it is wise to ship to a central location. Edge computing lets you course of this information domestically, sending solely most likely probably the most associated information to your central packages. For example, it could solely transmit data when temperatures exceed common ranges instead of sending mounted temperature readings.

- Additional Delicate Analysis: Edge devices can run difficult analysis packages that shall be impractical to run remotely. For instance, they’re going to analyze real-time vibration patterns to detect delicate changes that will level out rising points. This kind of quick, detailed analysis could possibly be troublesome or unattainable if the knowledge wanted to journey to a distant location first.

This improvement enhances reliability and agility in maintenance, empowering organizations to deal with operational hurdles proactively.

8. The Rising Significance of Repairs Metrics

By 2025, maintenance metrics will proceed to play an essential operate and assist in strategic decision-making. Along with AI and analytics devices, these metrics will

Repairs and facility managers and organizations increasingly rely upon refined analytics to evaluate and benchmark effectivity all through various dimensions, guaranteeing ongoing enchancment and accountability.

- Indicate Time to Restore (MTTR) highlights restore effectivity and minimizes gear downtime.

- Asset utilization costsassure gear operates at optimum functionality.

- Monitoring these metrics in real-time empowers organizations to pinpoint inefficiencies, strategically allocate belongings, and align maintenance efforts with overarching enterprise targets.

- Key metrics moreover embrace monitoring uptime and unplanned asset downtime.

- Deliberate maintenance proportion: is usually a key metric, calculated as (deliberate maintenance hours / entire maintenance hours) * 100%.

The cope with metrics reveals a switch within the route of data-driven maintenance, the place insights are used to boost effectivity and effectivity.

9. Net of Points (IoT) Integration

IoT devices have continued to proliferate in maintenance organizations. In 2025, we anticipate this improvement to proceed.

In a standard maintenance environment, machines operate independently. Every little bit of equipment works independently, and we rely on periodic inspections or apparent failures to know when one factor desires consideration. It’s like having a gaggle working in separate rooms and unable to talk.

IoT changes this by giving gear the pliability to talk. Proper right here’s the way in which it really works: Small sensors are related to completely totally different parts of your gear – think about these as a result of the gear’s “senses.” These sensors can detect temperature, vibration, pressure, velocity, and many totally different circumstances. Each sensor connects to a neighborhood, allowing it to share this information with totally different devices and your maintenance administration packages.

All these sensors ship their data to a central system, creating a complete picture of how each unit is performing. This brings quite a few extremely efficient benefits:

- Regular Monitoring: In its place of periodic checks, you now have 24/7 consciousness of how your gear is performing. The system can warn you immediately if one thing drifts exterior common parameters.

- Predictive Repairs: By gathering and analyzing data over time, IoT packages can research to predict when gear is vulnerable to fail. For example, they might uncover {{that a}} slight improve in vibration normally precedes bearing failure, allowing you to interchange bearings sooner than they break.

- System-Broad Optimization: On account of all your gear is linked, you probably can see how completely totally different elements impact each other. For example, you might uncover that points with one air handler are making others work extra sturdy to compensate.

- Larger Willpower Making: With detailed data about gear use, you might make larger maintenance scheduling and different selections. You might uncover that some objects need additional frequent maintenance whereas others could go longer between suppliers.

- Helpful useful resource Optimization: IoT could make it easier to optimize helpful useful resource use by displaying when and the place maintenance is required. This prevents over-maintenance (sustaining gear additional normally than obligatory) and under-maintenance (prepared too prolonged between suppliers).

Making an attempt to the long term, IoT continues to evolve with new capabilities:

- Self-diagnosing gear that will set up its points

- Automated maintenance scheduling based on exact gear state of affairs

- Integration with inventory packages to mechanically order different parts

- Cell apps that give maintenance teams on the spot entry to gear data

10. Additive Manufacturing

In 2025, additive manufacturing will proceed to develop for maintenance teams.

What exactly is additive manufacturing? Think about standard manufacturing, like carving a sculpture from a block of stone – you start with additional supplies than you need and scale back away the excess. Additive manufacturing works oppositely, setting up objects layer by layer, like stacking bread slices to make a sandwich.

Have an effect on on Repairs

This experience is very worthwhile for maintenance teams on account of it basically changes how we consider spare parts and repairs. In its place of sustaining large inventories of different parts or prepared weeks for specialised elements to achieve, maintenance teams can normally print what they need on demand.

Key Benefits for Repairs Teams

- Decreased Downtime: In its place of prepared days and even weeks for different parts, many elements could also be printed inside hours. This dramatically reduces gear downtime and its associated costs.

- Worth Effectiveness: Whereas the preliminary funding in 3D printing gear could also be very important, it normally pays for itself by:

- Reducing inventory costs: With 3D printing group, organizations can eradicate transport payments for emergency parts. 3D printing moreover permits the quick manufacturing of in some other case pricey personalized elements

- Design Flexibility: Repairs teams can modify half designs to deal with recurring failure elements and add reinforcement the place wished, enabling repairs of parts that will in some other case require full different.

- Preservation of Legacy Instruments: Additive manufacturing is normally a lifesaver for older gear the place parts are usually not accessible from producers. Teams can scan present parts to create digital fashions and recreate discontinued elements.

Making an attempt to the Future

The experience continues to evolve, bringing new capabilities:

- Faster printing speeds

- Additional supplies selections

- Larger ground finishes

- Elevated precision

- The facility to print parts with embedded sensors

Challenges and Options

Whereas these traits present very important options, there are challenges to beat. Integrating new utilized sciences into legacy packages requires funding and expertise, and bridging workforce capacity gaps requires robust teaching initiatives.

Cybersecurity stays a key concern as linked packages turn into additional integral. Nonetheless, these challenges moreover present options for organizations eager to innovate and adapt to the enterprise’s evolving requires.

Conclusion

The maintenance enterprise in 2025 and previous will doubtless be outlined by technological innovation, sustainability, and a cope with workforce progress.

From AI-driven insights to agile frameworks and immersive utilized sciences, the traits transforming maintenance are poised to redefine its have an effect on all through various industries.

Firms that adapt to this evolution will enhance their effectivity and dependability and arrange themselves as frontrunners in a swiftly progressing operational environment.

Repairs has developed previous guaranteeing efficiency—it is about forging a path in direction of a resilient, sustainable, and revolutionary future.