Get a Free WorkTrek Demo

Let’s current you methods WorkTrek can help you optimize your repairs operation.

Try with out spending a dime

An operations and maintenance Information is important for establishing owners and facility managers. It provides crucial particulars a few facility’s strategies, gear, and maintenance requirements.

This entire doc gives detailed operational guidance and maintenance information, ensuring environment friendly operation and longevity of the belongings for quite a few stakeholders, along with engineers and maintenance personnel.

These manuals perform full guides for managing sophisticated strategies successfully. They embrace detailed instructions, diagrams, and schedules important for retaining a facility working simply.

Creating an O&M Information is often a requirement after enterprise completion or for contractor handoffs. It compiles all the information on a establishing’s operation, repairs, decommissioning, and demolition, making it a helpful helpful useful resource all by way of a facility’s lifecycle.

Key Takeaways

- O&M Manuals current essential information for working and sustaining facility strategies

- These paperwork assure right functioning, longevity, and compliance with legal guidelines.

- Widespread updates to O&M Manuals are important for sustaining their relevance and usefulness.

Defining Operations and Repairs (O&M) Manuals

An O&M information is a key doc that guides the operation and upkeep of equipment and strategies. It accommodates crucial information for proper use, care, and maintenance to keep up points working simply and safely.

Goal of O&M Manuals

O&M manuals are essential guides for working and sustaining a establishing’s strategies. They help lengthen asset lifespans, in the reduction of costs, and assure fixed organizational procedures.

O&M manuals current step-by-step instructions for routine duties, serving to cease errors and enhancing effectivity.

This priceless helpful useful resource outlines safety protocols to protect employees and kit. It could probably moreover embody electrical, fire safety, and whole gear coping with guides.

O&M manuals present troubleshooting strategies for sophisticated strategies. The next suggestions can tempo up repairs and reduce downtime. The manuals moreover act as teaching devices for model spanking new staff.

Parts of O&M Manuals

An ideal O&M information has a lot of key parts:

- Instruments particulars and technical specs

- Working procedures and controls, along with machine working procedures

- Repairs schedules and checklists

- Safety suggestions and emergency procedures

- Troubleshooting guides

- Parts lists and diagrams

Environment friendly O&M manuals current repairs staff with detailed guidance. They embody information on right gear use and care, and clear instructions help avoid dear errors.

Repairs schedules are essential parts. They itemizing required duties and their frequency, which helps cease breakdowns and lengthen gear life.

Benefits of an O&M Information

An Operation and Repairs (O&M) information gives fairly a couple of benefits to organizations, making it an indispensable instrument for setting pleasant facility administration. Listed under are some key advantages:

- Improved Operational Effectivity: An O&M information provides detailed instructions on working and sustaining gear, lowering the prospect of human error and rising productiveness. Following the following pointers permits staff to hold out duties additional efficiently, ensuring clear operations.

- Enhanced Safety Applications: Safety procedures and protocols outlined in an O&M information help cease accidents and assure a protected working environment. This protects staff and minimizes the prospect of dear disruptions due to safety incidents.

- Lowered Downtime: Widespread repairs and troubleshooting procedures detailed in an operational information lower gear downtime. By adhering to these suggestions, repairs personnel can quickly sort out factors, lowering the have an effect on on operations and revenue.

- Elevated Asset Lifespan: Appropriate repairs and operation of equipment, as specified by an O&M information, lengthen the lifespan of belongings and in the reduction of repairs costs. This reduces the need for dear replacements and ensures that gear stays in optimum scenario for longer intervals.

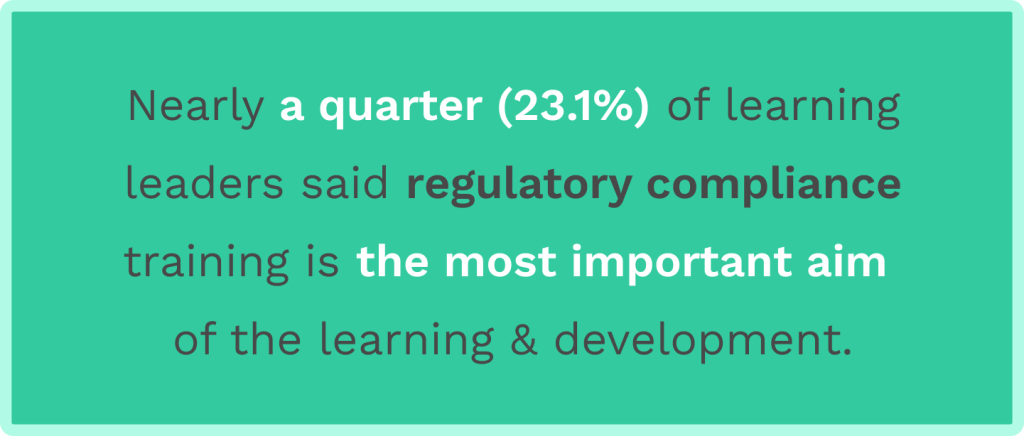

- Compliance with Legal guidelines: An O&M information ensures compliance with commerce legal guidelines and necessities, lowering the prospect of fines and penalties. Following the documented procedures, organizations can reveal due diligence and adherence to licensed requirements.

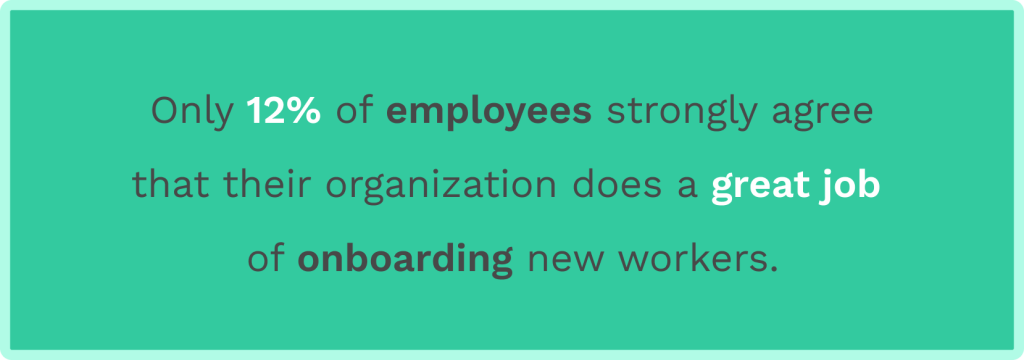

- Improved Teaching: An operations information is efficient for teaching new staff. It provides full information on gear operation and maintenance, along with seen aids. This reduces the time and operational worth associated to onboarding and ensures that new staff are well-prepared for his or her roles.

Who Needs an O&M Information?

An O&M information is essential for quite a few facility administration and operations stakeholders. Listed under are the essential factor groups that revenue from these full paperwork:

- Facility Managers: Accountable for overseeing the maintenance and operation of equipment. They rely upon O&M manuals to ensure compliance with legal guidelines and commerce necessities. These manuals current the obligatory information to deal with establishing strategies efficiently.

- Repairs Personnel: Repairs personnel use O&M manuals to hold out routine repairs, troubleshoot factors, and restore gear. The detailed instructions and schedules help them carry out their duties successfully and exactly.

- Operations Teams: Operations teams rely upon O&M manuals to ensure gear is operated appropriately, lowering the prospect of accidents and downtime. By following the documented procedures, they’re going to hold clear and guarded operations.

- Safety Officers: Safety officers use O&M manuals to ensure safety protocols and legal guidelines compliance. These manuals help them set up potential hazards and implement measures to cease accidents and accidents.

- Regulatory Our our bodies: Regulatory our our bodies use O&M manuals to ensure commerce legal guidelines and necessities compliance. These paperwork present {that a} company is adhering to licensed requirements and sustaining safety necessities.

The Significance of O&M Manuals in Mission Provide

O&M manuals play an essential place in worthwhile enterprise handovers. They assure clear transitions, swap key information and help meet licensed requirements.

Ensuring Simple Handover

O&M manuals are essential for clear enterprise handovers and are important sources for a facility’s repairs workforce. They provide detailed instructions on working and sustaining strategies, gear, and facilities. This information helps new owners or operators quickly understand one of the simplest ways to run points efficiently.

The manuals embody:

These particulars allow a seamless transition from the event workforce to the end-users. They in the reduction of downtime and forestall dear errors by way of the preliminary operational part.

Facilitating Data Change

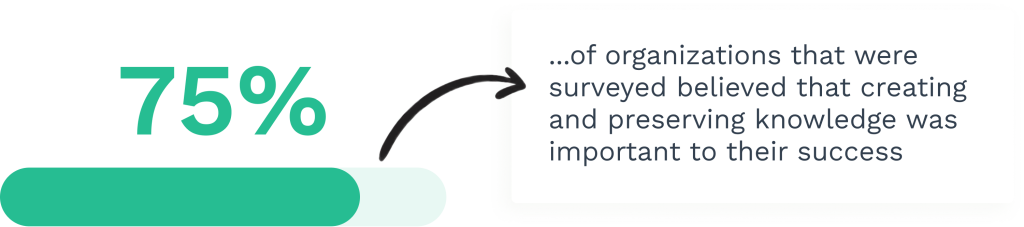

O&M manuals perform a whole information base. They seize the expertise of various enterprise stakeholders, along with:

- Engineers

- Contractors

- Instruments producers

- Safety specialists

This collected data ensures that essential information is simply not misplaced when the enterprise workforce strikes on. New staff can seek the advice of with the information for guidance, lowering the coaching curve and minimizing errors.

The manuals moreover current a single provide of truth for all operational factors. This helps resolve disputes and retains everyone on the an identical net web page.

Compliance and Licensed Obligations

O&M manuals are generally required for licensed and regulatory compliance. They reveal {{that a}} enterprise meets commerce necessities and safety requirements.

Key compliance factors embody:

- Environmental legal guidelines

- Effectively being and safety suggestions

- Establishing codes

- Assure circumstances

O&M manuals defend owners from licensed factors by documenting compliance. Moreover they perform proof of due diligence in audits or inspections.

Appropriate manuals can help protected insurance coverage protection safety and may be important for buying occupancy permits. They current that the flexibility is ready for protected and setting pleasant operation.

Biggest Practices for Creating O&M Manuals

Creating an environment friendly Operations and Repairs (O&M) information requires cautious planning and execution. The following practices help be certain the information serves its goal correctly.

Inclusiveness and Detailing for Repairs Personnel

An O&M information should cowl all gear operation and maintenance factors and embody detailed descriptions of strategies, parts, and procedures.

A repairs information template ensures the documentation is thorough and a reliable helpful useful resource for establishing operators and maintenance personnel.

The information should current step-by-step instructions for routine duties, troubleshooting guides, and safety protocols. Diagrams, flowcharts, and photos could make clear sophisticated information.

Along with a desk of contents and index makes discovering specific information less complicated. Technical specs, assure particulars, and name information for help additionally must be included.

Client-Nice Codecs

The information’s format performs a key place in its usefulness. A well-organized building with clear headings and subheadings improves navigation.

Using plain language and avoiding jargon makes the content material materials accessible to all prospects. Fast paragraphs and bullet components help break up textual content material and highlight important information.

Digital codecs allow for simple updates and searchability. Interactive elements like hyperlinks and pop-up definitions can enhance the buyer experience.

Holding Information Up-to-Date

Widespread updates are important for sustaining the information’s relevance and accuracy. A schedule for reviewing and revising the information must be established.

Changes in gear, procedures, or legal guidelines needs to be promptly mirrored throughout the information. Involving a lot of departments throughout the change course of ensures full revisions.

A mannequin administration system helps monitor changes and ensures prospects have entry to primarily essentially the most current information. It could probably moreover notify associated staff members of updates.

Utilizing O&M Manuals for Repairs and Operations

O&M manuals perform crucial devices for facilities teams. They info daily duties, help cope with emergencies, and help ongoing enhancements. Appropriate use of these manuals ensures clear operations and extends gear life.

Routine Repairs Procedures

O&M manuals current detailed instructions for regular upkeep of strategies and kit. They outline step-by-step processes for duties like:

- Daily checks and inspections

- Weekly or month-to-month cleaning routines

- Scheduled half replacements

- Lubrication and calibration procedures

These guides help staff perform repairs appropriately and on time. This prevents breakdowns and extends gear lifespan.

Manuals usually embody checklists and logs. These devices help monitor achieved work and spot potential factors early. By following the information’s procedures, teams can in the reduction of shocking downtime and restore costs.

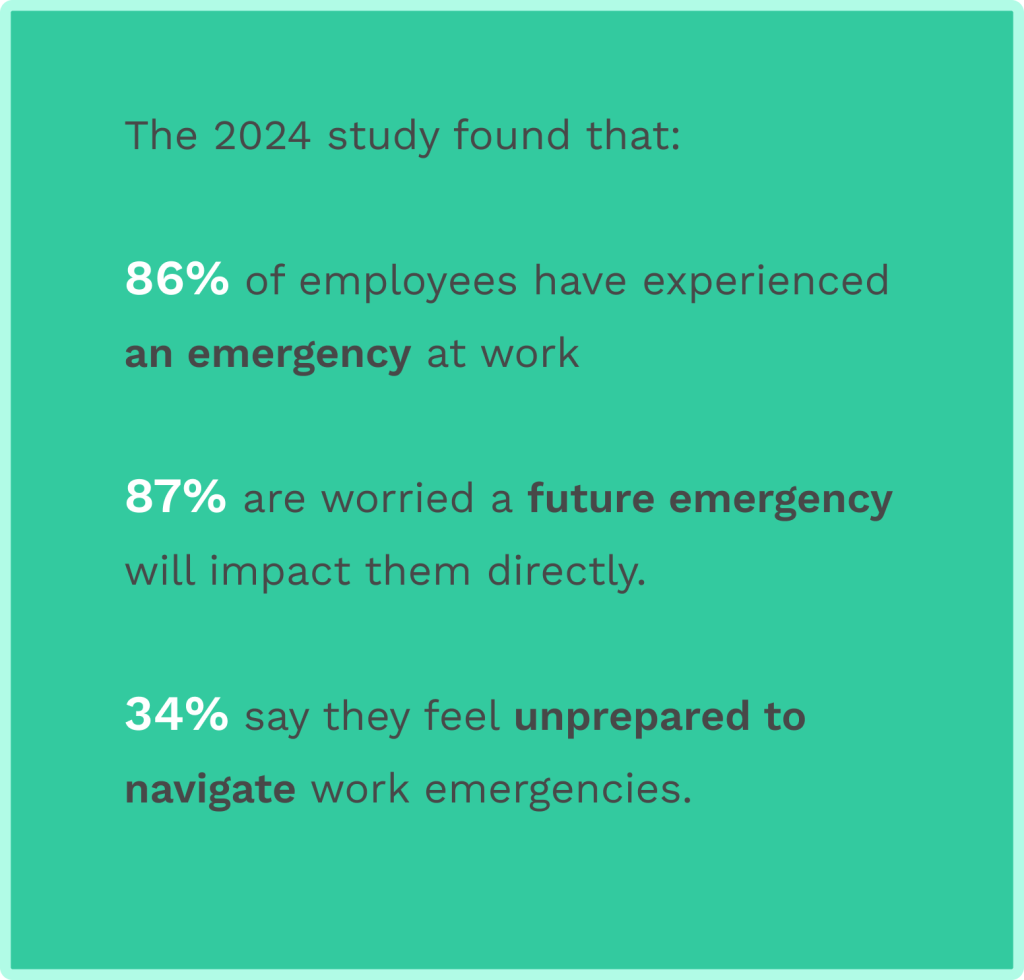

Emergency Response and Safety Procedures

O&M manuals embrace important information for coping with urgent situations. They itemizing widespread emergencies and steps to cope with them quickly.

Key elements usually embody:

- Emergency shutdown procedures

- Safety information and kit areas

- Contact lists for specialised technicians or distributors

- Detailed information, along with diagrams exhibiting essential system parts

- Repairs suggestions

- Operation instructions

- Repairs of fireplace safety strategies

Clear protocols help staff react swiftly and safely all through crises. This might cease accidents, limit harm, and in the reduction of restoration time.

Manuals might also outline steps for system restarts after emergencies. This ensures a clear return to common operations.

Effectivity Monitoring and Enhancements

O&M manuals help ongoing system optimization. They provide benchmarks and techniques for monitoring effectivity over time.

Very important factors embody:

Widespread monitoring helps set up inefficiencies or declining effectivity early. This allows for properly timed modifications or repairs.

Manuals might counsel enhance paths or optimizations as strategies age.

They may info decisions on when to revive versus substitute gear. This information helps facilities teams plan budgets and improve long-term effectivity.

O&M Manuals as Residing Paperwork

O&M manuals need frequent updates to stay purposeful. They should mirror the latest changes and enhancements in establishing strategies and operations.

Significance of Updates and Revisions

O&M manuals needs to be saved up-to-date to remain priceless. As buildings and kit change over time, the information ought to moreover change.

Widespread updates assure staff have the precise information to perform and hold strategies safely and efficiently.

This helps cease errors and retains the establishing working simply.

Outdated manuals may end up in errors, inefficiency, and even safety risks. By updating the information, facility managers can:

- Restore errors or unclear instructions

- Add new gear or strategies

- Take away information about retired gear

- Embrace improved procedures

- Define emergency protocols

- Define top quality administration procedures

Incorporating Solutions and Courses Realized

O&M manuals get increased as soon as they embody real-world experience. Staff strategies and courses from daily operations make the information additional useful.

Managers ought to rearrange a system to assemble enter from repairs teams and establishing prospects. This may increasingly very properly be through frequent conferences or a simple sort.

Key areas to focus on:

- Widespread factors confronted by staff

- Methods for increased procedures

- Notes on gear quirks or specific needs

- Safety concerns or near-misses

By together with this information to the information, future staff can revenue from experience.

This leads to smoother operations and fewer repeated errors.

Widespread opinions help spot developments and recurring points. These insights can info teaching, upgrades, and course of enhancements.

Technological Developments in O&M Information Administration

New digital devices and good strategies are altering how O&M manuals are created and used. These enhancements make manuals additional useful and less complicated to entry.

Digital Documentation

Digital O&M manuals are altering paper variations. They’re usually updated quickly and accessed from anyplace, and cloud storage retains the latest information on the market to all prospects.

Digital manuals usually use searchable textual content material, which helps employees uncover what they need. Some strategies moreover let teams add notes or flag factors throughout the information.

Many firms now use specific software program program to create digital manuals. These devices can pull info from completely different strategies and make it simple in order so as to add photos and flicks.

Interactive and Good Manuals

Trendy O&M manuals have gotten interactive. They might embody:

- 3D fashions of equipment

- Step-by-step films for duties

- Digital actuality teaching modules

Good manuals can hyperlink to dwell info from machines. This helps employees see real-time information as they work.

Some manuals now use AI to counsel fixes based mostly totally on indicators. They may moreover research from earlier factors to current increased suggestion over time.

Mobile apps for O&M manuals let employees entry information on their telephones, which is useful for space work or quick checks.

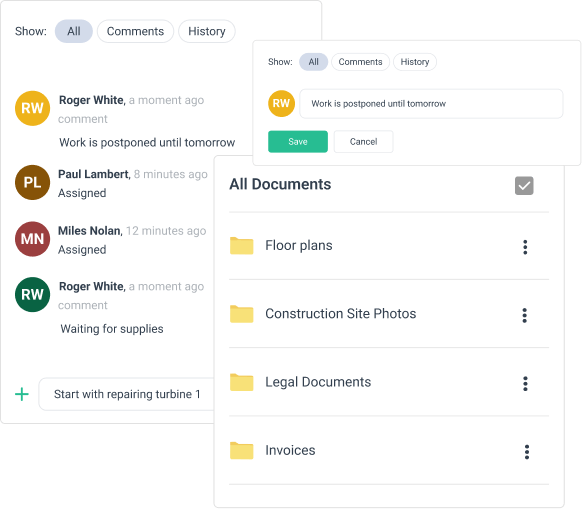

Integrating with a Associated CMMS

Integrating an O&M information with a Computerized Repairs Administration System (CMMS) like WorkTrek gives fairly a couple of benefits, enhancing repairs operations’ whole effectivity and effectiveness.

Listed under are some key advantages:

- Centralized Repository: CMMS provides a centralized repository for all O&M manuals, ensuring simple accessibility and lowering the prospect of misplaced or outdated paperwork. This centralized technique streamlines information administration and improves accessibility for repairs personnel.

- Automated Workflows: CMMS automates workflows, ensuring repairs personnel receive notifications and assignments promptly. This reduces the prospect of missed repairs duties and ensures all important actions are achieved on time.

- Precise-Time Updates: A associated CMMS permits real-time updates to O&M manuals, ensuring that repairs personnel can entry primarily essentially the most up-to-date information. That’s important for sustaining accuracy and relevance in repairs procedures.

- Data Analysis: CMMS provides info analysis capabilities, enabling organizations to hint repairs actions, set up developments, and optimize operations. This data-driven technique helps make educated decisions and improve whole repairs effectivity.

- Improved Compliance: CMMS ensures compliance with commerce legal guidelines and necessities, lowering the prospect of fines and penalties. By sustaining right and up-to-date O&M manuals, organizations can reveal adherence to licensed requirements and safety protocols.

By integrating O&M manuals with a associated CMMS, organizations can enhance their repairs operations, improve compliance, and ensure the longevity and effectivity of their gear and strategies.

Case Analysis and Examples of Environment friendly O&M Manuals

The O&M information for a low-carbon establishing demonstrates how these paperwork can bridge the opening between design and operation.

This case analysis highlights the information’s place in sustaining vitality effectivity and lowering carbon emissions.

A producing plant utilized interactive checklists of their O&M information. These checklists had been built-in into work orders, ensuring actual exercise execution and enhancing repairs effectivity.

A hospital used a cloud-based platform to create and deal with its O&M information. This technique allowed for real-time updates and simple accessibility for workers, major to raised gear upkeep and decreased downtime.

An office establishing’s O&M information included detailed vitality administration procedures.

This resulted in a 15% low cost in vitality consumption over two years.

A water remedy plant’s O&M information featured:

- Clear gear diagrams

- Step-by-step repairs guides

- Troubleshooting flowcharts

These elements led to faster problem determination and improved plant effectivity.

A university district’s O&M information included QR codes linking to tutorial films.

This progressive technique improved staff teaching and decreased repairs errors by 30%.

Challenges and Pitfalls in O&M Information Preparation

Making a wise O&M information could possibly be robust. Widespread factors embody missing key information and making the content material materials troublesome to utilize. However, there are strategies to avoid these points and create a better information.

Widespread Errors and Missed Aspects

Many O&M manuals lack clear instructions, which could confuse prospects. Some manuals moreover miss essential particulars about gear repairs.

One different problem is outdated information. The information moreover needs updating as strategies change, nevertheless this step is often forgotten.

Poor group is a frequent downside. The information loses value if prospects can’t quickly uncover what they need.

Some manuals use an extreme quantity of technical language. This makes it laborious for all staff to understand.

Ignoring shopper strategies is a gigantic mistake. The people using the information daily usually have the proper enter for enhancements.dugita

Mitigating Risks in O&M Information Creation

To avoid errors, start with a clear plan. Outline what the information should cowl sooner than writing begins.

Use a workforce technique. Get enter from engineers, operators, and maintenance staff to guarantee that all important information is included.

Widespread opinions are key. Prepare a schedule to look at and change the information, retaining the content material materials current and useful.

Make the information simple to utilize. Use clear headings, tables, and diagrams. An ideal format helps prospects uncover information quickly.

Check out the information with exact prospects. Their strategies can degree out areas that need enchancment.

Consider using digital codecs. Digital manuals could possibly be less complicated to interchange and search than paper variations.

Summary

An Operations and Repairs (O&M) Information is a vital doc for facility administration that provides full guidance on working and sustaining establishing strategies and kit.

These manuals are essential sources for facility managers, repairs personnel, operations teams, and safety officers. They embrace detailed instructions, diagrams, and schedules for proper facility operation.

The essential factor benefits of O&M manuals embody improved operational effectivity, enhanced safety strategies, decreased downtime, elevated asset lifespan, regulatory compliance, and better staff teaching.

They play an essential place in enterprise handovers by ensuring clear transitions and information swap.

Biggest practices for rising O&M manuals embody sustaining full ingredient, using user-friendly codecs, and retaining information current. Trendy O&M manuals are an increasing number of digital, that features interactive elements and integration with Computerized Repairs Administration Applications (CMMS).

Widespread updates are essential to reflect changes in gear, procedures, or legal guidelines, making them environment friendly “residing paperwork” that evolve with the flexibility’s needs.