Take into consideration the final meal you had. Earlier than it reached your plate, it handed by means of a meals warehouse, one which stored it contemporary, secure, and prepared for supply. Meals warehousing isn’t nearly storage; it’s an essential part of the meals provide chain.

From temperature management to strict security rules, meals warehouses have so much on their plate. A small slip (like improper dealing with or mishandling) can result in spoiled meals, monetary losses, and even well being dangers.

Meals warehouse operators should stability:

- Exact temperature administration

- Contamination prevention

- Stock management

- Tight supply schedules

That’s why now we have created this information.

Whether or not you run a small storage facility or a big meals distribution heart, this information will stroll you thru the whole lot you could learn about meals warehousing and food-grade storage amenities.

What’s Meals Warehousing?

Meals warehousing means storing meals earlier than being bought or distributed round. Working a meals warehouse might require expertise, experience, and energy. They need to give attention to sustaining correct well being & sanitation to guard the meals.

One of many greatest challenges meals warehouses face is thrashing the time as a result of there’s a meals expiration date within the image. Additionally, dairy and frozen merchandise might get spoiled if stored on the mistaken temperature for too lengthy.

Why it’s Essential?

As we now know what meals warehousing is, allow us to verify what its significance is:

- Warehousing permits optimized distribution and well timed supply

- Correct meals storage helps to reduce the chance of meals spoilage

- The warehouse works with most effectivity leading to higher buyer satisfaction

- It helps to protect the standard and dietary worth of the meals

- Meals-grade storage prevents foodborne sickness attributable to dangerous micro organism

- Warehousing reduces the possibilities of errors and harm within the order achievement course of

Important Meals Warehousing Necessities

Beneath are the sure necessities for meals warehousing:

- Operating a meals warehouse might require some certifications, working procedures, and moral organizational tradition. These certificates will guarantee meals security requirements all through the meals and beverage trade.

- Earlier than any meals warehousing firm operates, it should register with the Meals and Drug Administration (FDA). This registration is the duty of the proprietor or the managing member. Registering with the FDA will probably be subjected to annual inspections and required to observe the ideas of food-grade storage.

- The warehouse ought to maintain a state license and in addition adhere to tips of the Meals Security Modernization Act (FSMA).

Most important Parts of Meals Warehousing

Listed below are the principal components of meals warehousing that it’s best to know :

1. Distribution centres

Correct planning of house inside a warehouse and positioning objects helps to enhance effectivity. It provides to vital time and monetary financial savings. The house planning ought to embrace inbound receiving bays, storage areas, parking areas, and outbound loading docks.

2. Obtain incoming shipments

Warehouse receiving is step one in eCommerce achievement. It includes delivering, unloading, and storing merchandise in a warehouse. Receiving incoming shipments contains inspecting the situation, high quality, and amount of any incoming items and allocating them to an area within the warehouse.

Additionally, ensure that the packaging must be intact and clear to stop it from being contaminated. Delivered merchandise must be labeled appropriately and include the correct documentation.

3. Stock administration

A straightforward-to-use and strong warehouse administration system is one of the simplest ways to trace all of the actions inside a warehouse. This software program permits visibility into all the stock and manages provide chain achievement operations from distribution facilities to the shop shelf. Small companies usually use a logbook to maintain observe of stock.

For instance, stock administration software program can observe the circulate out and in of things from the warehouse. It might probably additionally discover the present stock standing and plan accordingly for future necessities.

4. Storage of meals merchandise

After receiving and processing merchandise, the following factor to do is retailer them. It includes placing them in bins and pallets and transporting them to acceptable space for storing. Acceptable storage maintains each the standard and dietary worth of the meals.

There are three kinds of meals storage choices at warehouses:

- Dry storage refers to storing of things that don’t require a managed temperature

- Refrigerated storage requires a cool however not freezing temperature

- Frozen storage means conserving merchandise at a freezing temperature

5. Keep required temperature

Relying on the character of the merchandise, it’s important to retailer the meals at an acceptable temperature. It might probably embrace the humidity, temperature, and stress required to maintain specific meals merchandise.

Managed temperature for particular meals objects ensures upkeep of the standard of meals and prevents it from spoilage.

6. Reorganizing

When the brand new merchandise arrive on the warehouse, the present inventories want reorganization to make sure that the warehouse house will get utilized effectively. Any occasion of adjustments must be tracked and up to date within the warehouse administration system.

7. Decide-up and dispatch

Lastly, when the product is prepared for pick-up or cargo, the warehouse workers should retrieve, course of, pack, and cargo it for launch. It would assist to create space for the brand new inbound merchandise within the stock.

Meals-Grade Warehousing: All the things You Ought to Know

What’s food-grade warehousing?

Meals-grade warehousing refers to storage amenities particularly designed to deal with meals merchandise safely. Not like commonplace warehouses, these amenities observe strict hygiene, temperature management, and meals security protocols to stop contamination, spoilage, and regulatory violations.

Consider food-grade warehousing as a specialised model of normal warehousing however with a lot stricter guidelines and better requirements.

What makes a warehouse “Meals-Grade”?

A food-grade warehouse isn’t nearly storing meals; it’s about defending it. Each side of the power wants particular consideration, from the constructing supplies to day by day operations.

The flooring, partitions, and ceilings should be food-grade licensed, which suggests they’re simple to wash, non-toxic, and immune to chemical substances. The power wants correct drainage, enough lighting, and air flow techniques that preserve constant air high quality.

Key necessities of a food-grade warehouse

Meals warehouses don’t simply stack containers—they preserve a managed atmosphere the place meals stays secure from contamination, spoilage, and pests. Listed below are the essential elements that make a warehouse “food-grade”:

- Strict hygiene requirements: Warehouses should be clear, repeatedly sanitized, and free from pests. Even minor contamination could make meals unsafe.

- Temperature & humidity management: Completely different meals want completely different circumstances. Recent produce, frozen objects, and dry items all require exact temperature and humidity ranges.

- Correct air flow & air high quality: Clear, well-circulated air prevents mould, micro organism, and odors from affecting saved meals.

- Protected dealing with & storage: Meals should be saved in FDA-approved containers off the ground, away from chemical substances, and dealt with with care to stop harm or contamination. For perishable items observe the FIFO (First In, First Out) technique to stop expired objects from being shipped.

- Regulatory compliance: Meals warehouses should adjust to rules from companies just like the FDA (Meals and Drug Administration), USDA (United States Division of Agriculture), and native well being authorities. They need to get hold of meals storage licenses and meet HACCP (Hazard Evaluation Vital Management Level) requirements.

Document-keeping is a should in food-grade warehousing

In food-grade warehousing, correct documentation is crucial. You have to observe:

- Product places and actions

- Temperature readings

- Cleansing schedules

- Upkeep actions

- Worker coaching

This documentation protects each you and your clients, and it’s usually required for compliance with meals security rules.

Sorts of food-grade warehouses

Completely different meals have completely different storage wants, and food-grade warehouses are outfitted to deal with all of them. Right here’s what you could learn about every sort:

- Dry storage: That is for shelf-stable objects like canned meals, packaged meals, and grains. These areas want low humidity and good air circulation. Whereas the temperature necessities aren’t as strict as different varieties, you continue to want to watch circumstances rigorously.

- Refrigerated storage: Recent produce, dairy, and a few processed meats want refrigerated storage. These areas preserve temperatures between 33°F and 39°F. Correct air circulation is critical to stop chilly or sizzling spots that might have an effect on meals high quality.

- Frozen storage: For frozen meals, temperatures should keep at or under 0°F. These areas want highly effective cooling techniques and wonderful insulation. Backup energy techniques are important as a brief energy outage might compromise whole shipments.

- Local weather-controlled storage: Some specialty meals, like chocolate or wine, want exact temperature and humidity management. These areas present probably the most rigorously regulated atmosphere within the warehouse.

One of many greatest challenges in food-grade warehousing is stopping cross-contamination. You want clear techniques to separate various kinds of meals, particularly conserving uncooked elements away from ready-to-eat merchandise. Allergen management is essential as a result of even tiny quantities of allergens may cause severe issues for customers.

Meals Warehousing vs. Meals-Grade Warehousing: What’s the Distinction?

Meals warehousing and food-grade warehousing might sound comparable, however the important thing distinction lies in security requirements and meals dealing with necessities.

- Meals warehousing shops meals merchandise earlier than distribution. It might embrace dry storage for packaged items and normal stock administration.

- Meals-grade warehousing follows strict hygiene, temperature management, and regulatory requirements to make sure meals security. It requires compliance with FDA, USDA, and HACCP rules, correct sanitation, and contamination prevention.

Briefly, in the event you’re dealing with perishables, frozen meals, or delicate meals objects, you want a food-grade warehouse with specialised security measures. In case you’re storing sealed, shelf-stable merchandise (merchandise with larger shelf life), a normal meals warehouse could also be sufficient.

What are the Finest Practices to Be Adopted for Meals Warehousing?

Practices to be adopted by Meals Grade warehousing are talked about under:

1. Correct hygiene and sanitation

The foundations governing hygiene and sanitation embrace the actions of workers and the warehouse facility. Meals grade warehouse prevents cross-contamination that may trigger meals allergens, pathogens, and sicknesses.

It’s primarily for uncooked items comparable to vegatables and fruits. Each individual working at a meals storage warehouse should wash their palms totally.

Additionally, coaching workers in high quality consciousness, incident & disaster administration, meals security, and private hygiene is a should.

2. Well timed pest management

A warehouse administration system isn’t a leisurely cup of tea. A meals security plan can forestall indoor and out of doors contamination. Well timed pest management might help forestall dry meals like rice and grain from getting contaminated.

For instance, routine surveys of the warehouse constructing might help to establish factors of entry for rodents, bugs, and different animals. As soon as these openings get positioned, they should be sealed or closed. Additionally, some managed substances within the warehouse will forestall these animals from getting into the premises.

3. Temperature course of controls

Periodic monitoring of the environmental circumstances of the warehouse prevents saved or frozen objects from getting contaminated or spoiled. Acceptable coaching for all the staff might help to sort out this downside if discovered.

Normal tips for the temperature of meals saved in a warehouse:

- The minimal temperature for frozen objects must be 0° F.

- The proper temperature required for storing chilled or refrigeration merchandise must be between 34° to 39° F.

- Dry storage merchandise want temperatures between 50° and 70°F.

NOTE: The humidity degree for dry storage shouldn’t be larger than 15%, and eatables shouldn’t be stored in direct daylight.

4. Maintaining document of the heaps

A warehouse will need to have a list administration system to hint the product heaps and dates following the First-In-First-Out technique.

On this technique, the primary unit loaded on the rack is the primary to go away. This slotting and retrieval technique ensures that perishable merchandise with an early expiry date are dispatched quickly.

Some Advantages of Automating Meals Warehousing

There’s an rising demand for automated options for warehousing by suppliers and clients. It’s required to meet logistics wants and handle shares effectively.

Beneath are some benefits of automating meals warehousing:

1. Accuracy in inventory administration

The automation will assist to handle the stock extra precisely. Stock accuracy calculates the distinction between your inventory data and precise bodily stock.

It will provide you with a greater understanding of your corporation and what number of merchandise you could meet buyer calls for. Additionally, it should forestall your corporation from operating out of things at any time.

Any enterprise must hold stock correct to maintain the availability chain and meals distribution course of clean. Warehouse administration software program and automatic storage prevents dealing with errors and ensures product traceability and firm response time.

2. Speedy transportation of products

Swiftness refers back to the firm’s capacity to regulate its working technique relating to procurement and stock administration. An automatic resolution will allow the uninterrupted circulate of merchandise between completely different warehouse areas.

It goals to fulfill buyer demand regardless of fluctuations so as quantity at any given time. A few of the options of a swift provide chain are:

- Demand forecasting & administration

- Finish-to-end collaboration

- Responsive techniques and analytics

- Threat administration

- Course of possession

3. Optimization of space for storing

Area optimization in a warehouse is when the structure permits for clean choosing, packing, and transport of orders. Automated house optimization will assist to establish compact areas and retailer extra items within the smallest space potential.

To enhance warehouse operations, contemplate the under factors:

- Optimize the house accessible within the warehouse

- Undertake new applied sciences

- Manage your workstations

- Optimize labor effectivity

4. Elevated effectivity and lowered guide labor

The automation of meals warehouses with superior applied sciences has boosted the manufacturing of the trade. Moreover, it has additionally made it extra environment friendly to establish potential points and resolve them.

Automation has additionally lowered guide labor work, comparable to inspecting equipment or assigning duties. With minimal human labor, the possibilities of human error are additionally lowered.

Following the advantages of automating meals warehousing, let’s understand how Higher might help ease the work for the meals and beverage trade.

How Higher Can Help Your Meals Warehousing Companies

Managing supply schedules, optimizing routes, and making certain well timed pickups and deliveries, are all a part of meals warehousing companies, which could be a lot to deal with.

That’s the place Higher might help.

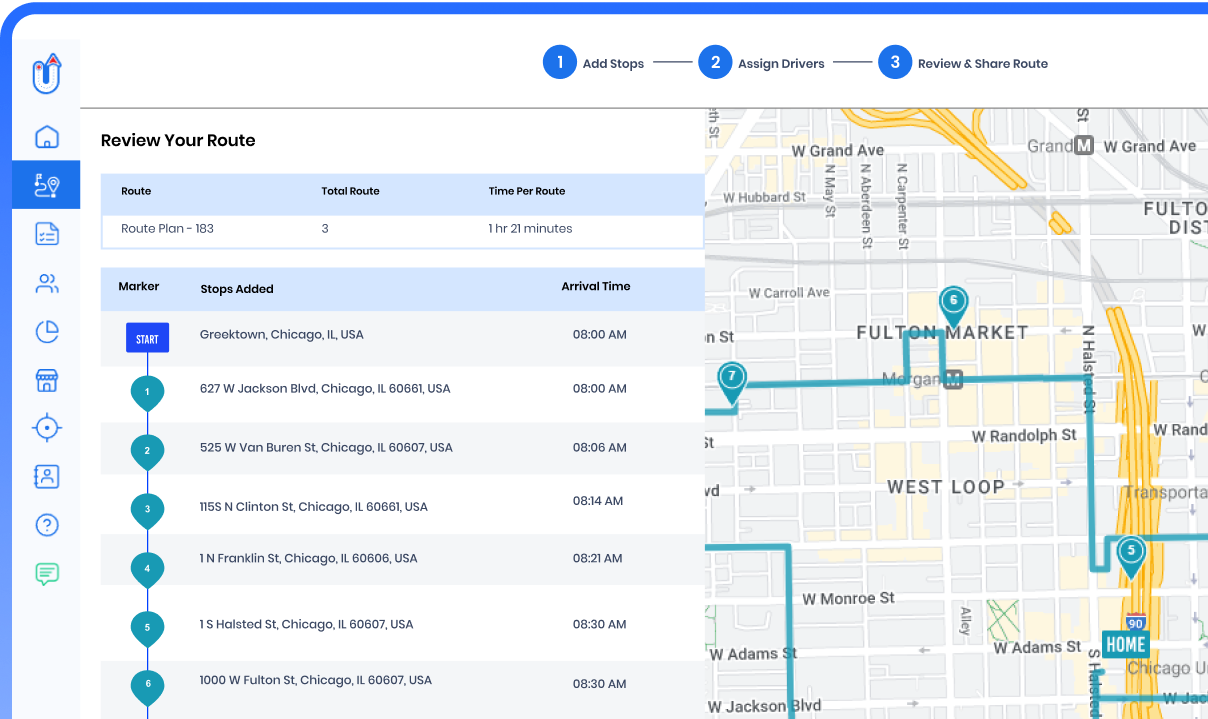

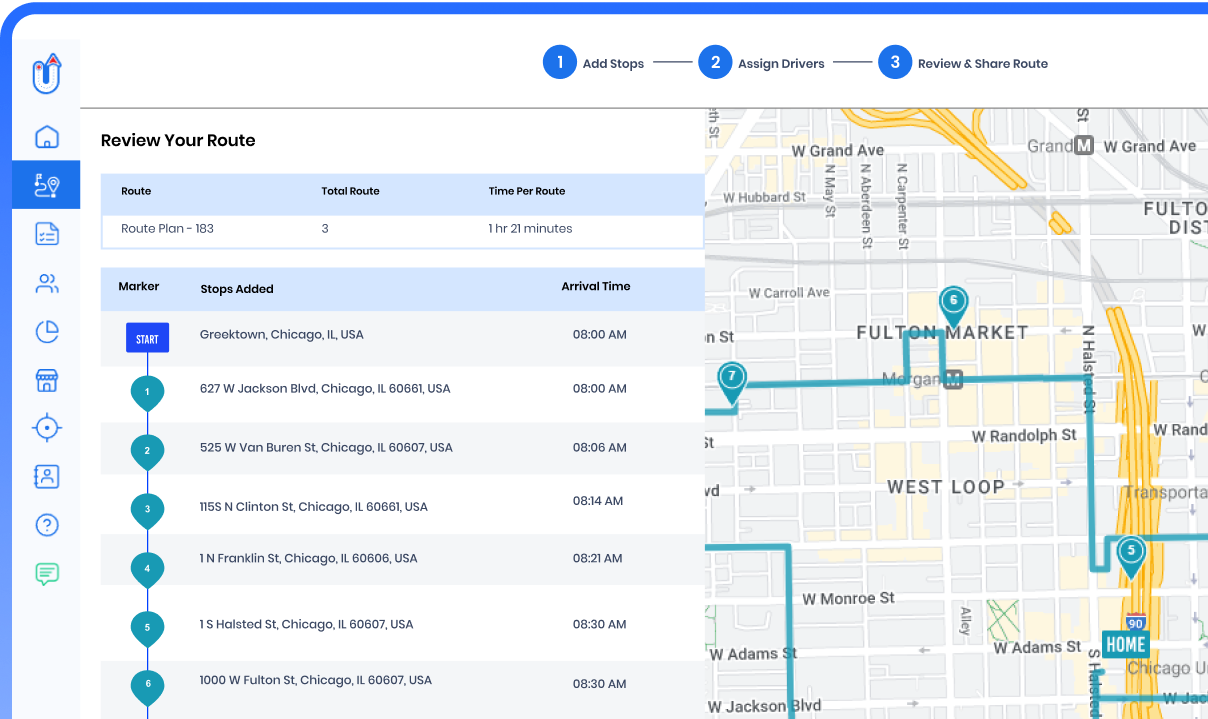

Let’s discuss dispatch and route planning first.

As a substitute of spending hours determining the perfect supply routes manually, Higher helps you create optimized routes in minutes. You’ll be able to import all of your supply addresses from a spreadsheet, set particular time home windows for deliveries, and Higher will calculate probably the most environment friendly routes in your drivers.

Need to be certain temperature-sensitive objects attain their vacation spot on time?

You’ll be able to set precedence ranges for pressing deliveries and add particular time home windows for every cease. This implies your frozen items and perishables get delivered inside their required timeframes, sustaining meals security requirements.

You’ll be able to even add service time for every cease, accounting for loading and unloading occasions at completely different warehouses or supply factors. This helps create extra correct supply schedules and retains your whole operation operating easily.

Must deal with each pickups and deliveries in the identical route?

Higher helps you to plan blended routes effectively, so your drivers can deal with each duties with out pointless back-and-forth journeys. This implies much less gas consumption and extra deliveries accomplished per day.

What about conserving your clients knowledgeable?

Higher sends automated notifications about supply standing and ETAs, so your clients at all times know when to anticipate their deliveries. That is particularly essential when coping with time-sensitive meals deliveries.

Trick to Simplify Your Warehouse Operations

Whether or not it’s managing supply schedules, time-sensitive deliveries, or dealing with pickups and drop-offs collectively, Higher manages your whole meals warehouse logistics simply.!

Begin Utilizing Higher![]()

![]()

FAQs

Warehouse operations are part of the meals provide chain that gives storage, processing, and different features. It means storing merchandise earlier than they’re bought or distributed round.

Correct hygiene and sanitation must be taken care of whereas storing meals in a warehouse.

Warehouses have completely different strategies for storing meals merchandise, from dry to freezer storage. All of it is determined by what meals is saved.

The 4 kinds of warehousing are:

- Public warehouse

- Non-public warehouse

- Co-operative warehouses

- Distribution facilities

Warehousing makes it simpler to obtain, retailer, and distribute items from a central location. This helps to cut back transportation prices and improve the worth of products.

Wrapping It Up

Meals warehousing is a essential hyperlink in our meals provide chain, demanding precision, care, and environment friendly administration.

For sure, storage is the first focus of meals warehousing, however sustaining the standard of meals merchandise and getting them to their vacation spot safely and on time is crucial too.

By implementing the precise practices and utilizing fashionable instruments like automated warehouse administration techniques and route optimization software program, you may handle your operations whereas making certain meals security requirements are met.

Begin small, give attention to the basics, and steadily construct up your capabilities.