Get a Free WorkTrek Demo

Let’s current you methods WorkTrek can help you optimize your maintenance operation.

Attempt with out spending a dime

Within the occasion you make use of a reactive maintenance method, you’ll need reactive maintenance software program program to cope with instruments breakdowns.

This extremely efficient software program helps companies quickly reply to stunning factors, defending operations working simply. It’s a wise different for lots of industries, from manufacturing to property administration.

Reactive maintenance software program program, resembling WorkTrek CMMS, offers key benefits, resembling sooner response events, increased helpful useful resource administration, and improved purchaser satisfaction.

Firms that make use of a CMMS, can cut back downtime, merely observe repairs and cut back maintenance costs. It helps teams work further successfully, guaranteeing the exact people are on the job on the correct time.

Key Takeaways

- Reactive maintenance software program program accelerates response events and cuts instruments downtime.

- It helps firms deal with property further efficiently and improve purchaser satisfaction.

- The experience permits increased monitoring, scheduling, and record-keeping for maintenance duties.

Exploring Reactive Repairs

So what exactly is reactive maintenance, and when do organizations use it?

Definition and Guidelines

Reactive maintenance is an methodology to maintenance that responds to breakdowns after they happen. It’s moreover known as “run-to-failure”, corrective or emergency maintenance.

Which signifies that maintenance organizations don’t perform frequent repairs on instruments and solely wait until the machine or instruments fails sooner than fixing it.

This course of is inexpensive for maintenance organizations as a result of it does not require a maintenance schedule or a preventive maintenance method.

Nonetheless, it is best suited to low-cost or easy-to-replace objects. As an illustration, gentle bulbs are generally modified solely after they burn out.

What makes reactive maintenance widespread? The tactic is straightforward and does not require superior planning or schedules. It moreover reduces the need for pointless maintenance.

Most organizations make this part of their maintenance program.

Comparability with Preventive Repairs

So how does this study to preventive or proactive maintenance?

Preventive maintenance tries to stop points sooner than they start by implementing routine maintenance. It makes use of frequent checks and upkeep to keep up machines working successfully.

Corrective maintenance is completely totally different. It solely presents with factors after they happen.

Preventive or corrective maintenance can worth further upfront. It requires frequent staffing, time for inspections, and customary parts storage.

Nonetheless, it is a confirmed methodology to chop again instruments failures and doubtlessly be inexpensive for essential instruments.

Decreasing emergency repairs can positively improve asset effectivity. Nonetheless, a proactive or predictive maintenance methodology is required.

Advantages of Implementing Reactive Repairs Software program program

Reactive maintenance software program program helps you implement an environment friendly reactive maintenance course of. Why would you like software program program to hint reactive maintenance?

Streamline Repairs Workflow

First, CMMS software program program can merely streamline the maintenance workflow via automated work order administration.

Workers can instantly submit maintenance requests via mobile apps or web interfaces when a little bit of equipment fails.

What’s way more spectacular is that CMMS methods, like WorkTrek, can mechanically route these requests based totally on pre-defined pointers and technical capabilities.

This might significantly cut back the information work in managing work orders and improve response time.

Gear Historic previous

One primary benefit of using a CMMS software program program for reactive maintenance is the supply of equipment and maintenance historic previous.

Every restore, half substitute, and maintenance train will get logged with detailed knowledge, along with timestamps, technician notes, parts used, and associated costs.

This historic file proves invaluable for diagnosing recurring factors.

As an illustration, technicians can analyze earlier maintenance info to find out patterns and underlying causes if a particular motor fails every few months fairly than merely treating indicators.

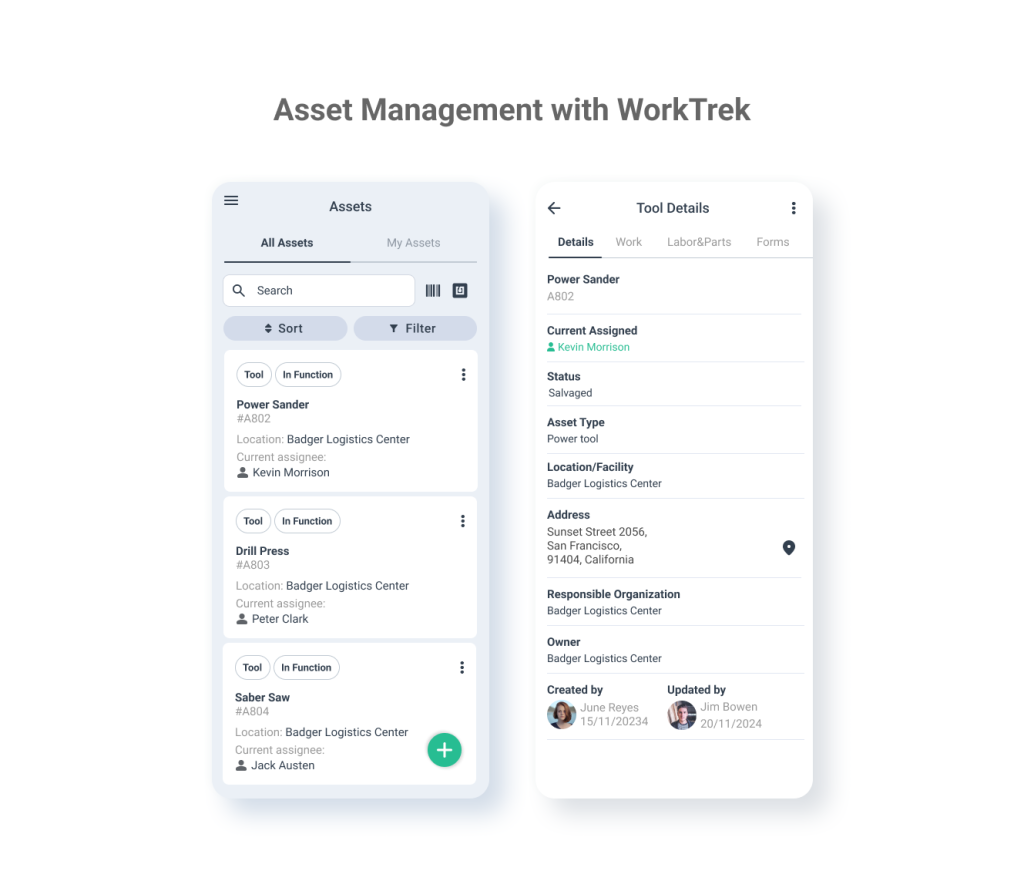

Asset Administration

Asset administration capabilities signify one different important revenue. CMMS tracks instruments specs, assure knowledge, spare parts inventory, and vendor contacts in a centralized database.

When instruments fails, technicians can immediately entry restore manuals, parts availability, and maintenance procedures. This eliminates time wasted looking for documentation or discovering that wanted parts aren’t in stock.

Reporting & Analytics

The reporting and analytics capabilities help organizations optimize their maintenance operations over time. Managers can analyze metrics like suggest time between failures, frequent restore costs, and labor utilization.

These insights enable data-driven alternatives about instruments substitute, maintenance staffing, and inventory administration. As an illustration, if restore costs for ageing instruments keep rising, the information can justify proactive substitute sooner than catastrophic failure occurs.

Mobile Devices

Mobile accessibility has revolutionized how technicians execute reactive maintenance. Using smartphones or tablets, they may entry work orders, instruments knowledge, and maintenance procedures correct on the extent of service.

They’ll moreover doc their work in precise time by importing pictures, updating parts utilization, and logging labor hours. This improved documentation leads to increased accountability and further appropriate maintenance info.

Possibly most importantly, CMMS software program program helps organizations transition from purely reactive maintenance to further proactive approaches.

The knowledge collected all through reactive maintenance work creates the muse for determining instruments that may revenue from preventive maintenance schedules or scenario monitoring. Over time, it will cut back your complete amount of reactive maintenance wished.

Operational Enhancements

Think about reactive maintenance software program program as a central nervous system for maintenance operations. Merely as your nervous system coordinates responses all by way of your physique, this software program program coordinates maintenance actions all through your facility. Let’s uncover how this coordination interprets into tangible operational benefits.

Low cost in Response Time

In all probability essentially the most quick revenue is the dramatically lowered response time to instruments failures. In a standard system, when a machine breaks down, the notification course of might comprise various steps:

- An operator notices the difficulty

- Fills out a paper sort

- Delivers it to maintenance

- Look ahead to someone to course of it.

Straightforward strategies to Improve the Course of Using a CMMS

With reactive maintenance software program program, the tactic is a lot simpler:

- Operator can instantly submit a bit order via their mobile machine

- System will create and mechanically assign the work order

- Operator shall be notified when the work is achieved.

Using the software program program drastically reduces the amount of information steps that clients ought to bear.

In the reduction of Knowledge Silos

One different very important operational profit comes from the elimination of data silos.

So what exactly are knowledge silos? That’s when maintenance technicians become specialists in a particular instruments kind, and that knowledge is not on a regular basis shared with the organizations.

With out specialised software program program, essential maintenance knowledge often exists in scattered areas – instruments manuals is maybe in submitting cabinets, spare parts inventory in spreadsheets, and maintenance histories in notebooks.

The beauty of reactive maintenance software program program is that every one this knowledge could also be centralized in a single, easy-to-access location.

Which signifies that any maintenance technician can merely entry this knowledge and restore the instruments.

Improve Inventory Administration

One in every of many largest challenges maintenance technicians face is having the required parts ready for restore or maintenance.

Having the exact parts accessible can cut back downtime and improve maintenance effectivity.

Having the exact reactive maintenance software program program in place moreover signifies that you have full visibility into what parts are in stock and which parts are on order and anticipated to achieve shortly.

Reactive maintenance software program program maintains real-time inventory monitoring, mechanically flagging low stock ranges and initiating purchase orders when gives run low.

This methodology ensures that essential spare parts may be discovered when wished.

Improve Labor Utilization

Labor is probably going one of many costliest parts of any maintenance group. Of us worth money; the aim is to boost utilization and cut back complete costs.

How are you going to do that? By implementing reactive maintenance software program program, it’s possible you’ll intelligently assign duties based totally on technician location, means set, and current workload.

This smart dispatching methodology eliminates the inefficiencies of information exercise job, the place technicians might crisscross the power various events or sit idle whereas others are overloaded. This might cut back breakdown maintenance instances.

The system might even account for shift modifications, guaranteeing essential maintenance duties are accurately handed off between teams.

Documentation and Compliance

the importance of defending up-to-date documentation for many who run a maintenance group. That’s very important for maintenance historic previous and potential audits.

Reactive maintenance software program program mechanically logs every movement with timestamps, technician identification, parts used, and detailed notes.

Having digital, easy-to-access info proves invaluable for regulatory compliance and assure claims.

Further importantly, it creates a searchable database of maintenance actions which will help decide patterns in instruments failure and inform future maintenance strategies.

Switch from Reactive to Predictive Repairs

One in every of many largest benefits of reactive maintenance software program program is that it permits organizations to rework from reactive to predictive maintenance.

Why is that this useful? Organizations implementing predictive maintenance strategies can cut back unplanned downtime and improve deliberate maintenance and stunning downtime.

The system can analyze maintenance info to find out instruments incessantly requiring reactive maintenance. This helps maintenance managers make data-driven alternatives about preventive maintenance schedules or instruments substitute.

Reactive maintenance has many disadvantages, along with stunning failures, intensive repairs, and potential safety risks.

A every day preventive maintenance methodology can exactly predict failures, improve routine inspections, and cut back long-term costs.

Asset Life Extension

Good reactive maintenance software program program helps machines final extra by guaranteeing that small points are mounted quickly.

When factors are caught early, they don’t set off as loads hurt. This means a lot much less placed on and tear on instruments over time.

The software program program retains detailed restore histories. This knowledge helps technicians understand each machine’s weak components.

With this knowledge, they may take steps to forestall future breakdowns. They might change parts sooner than they fail or modify maintenance schedules.

Elevated Gear Reliability

Reactive maintenance software program program boosts instruments reliability in various strategies. It helps create a practice of quick scenario response.

Workers often are inclined to report points immediately, and the software program program makes it easy to log factors and request help.

This leads to sooner repairs. Machines spend a lot much less time broken and further time working.

The system moreover learns from earlier breakdowns. It might counsel strategies to forestall comparable factors in the end. This proactive methodology retains instruments working simply for longer durations.

Operational Enhancements

Reactive maintenance software program program significantly upgrades companies’ coping with of equipment factors. It modifications every single day operations in various key strategies.

Precise-Time Information Monitoring and Analysis

Reactive maintenance software program program permits teams to hint restore needs as they happen. Workers can log points quickly using mobile devices.

This creates a clear file of all factors.

The software program program analyzes this info to establish tendencies. It might current which machines break down most ceaselessly and reveal frequent causes of failures.

Managers use these insights to make smart alternatives. They’ll give consideration to fixing recurring points. This helps forestall future breakdowns.

Increased Helpful useful resource Allocation

With reactive maintenance software program program, companies can use their workers and devices further accurately. The system helps assign duties based totally on urgency and worker experience.

It reveals which jobs need consideration first. This stops minor factors from turning into large points.

The software program program moreover tracks parts and gives and alerts managers when stock is low, guaranteeing teams have what they need for repairs.

Increased planning leads to a lot much less downtime. Workers spend further time fixing points and prepared a lot much less for parts or instructions.

Asset Life Extension

Good reactive maintenance software program program helps machines final extra by guaranteeing that small points are mounted quickly.

When factors are caught early, they don’t set off as loads hurt. This means a lot much less placed on and tear on instruments over time.

The software program program retains detailed restore histories. This knowledge helps technicians understand each machine’s weak components.

With this knowledge, they may take steps to forestall future breakdowns. They might change parts sooner than they fail or modify maintenance schedules.

Elevated Gear Reliability

Reactive maintenance software program program boosts instruments reliability in various strategies. It helps create a practice of quick scenario response.

Workers often are inclined to report points immediately, and the software program program makes it easy to log factors and request help.

This leads to sooner repairs. Machines spend a lot much less time broken and further time working.

The system moreover learns from earlier breakdowns. It might counsel strategies to forestall comparable factors in the end. This proactive methodology retains instruments working simply for longer durations.

Strategic Benefits

Reactive maintenance software program program offers key advantages for organizations. It enhances decision-making, helps meet guidelines, and helps eco-friendly practices.

Improved Willpower-Making Processes

Reactive maintenance software program program provides real-time info on instruments factors, allowing managers to make quick, educated alternatives about repairs.

The software program program tracks the restore historic previous and costs for each asset.

Managers can use this info to establish tendencies and plan increased. They’ll decide when to modify outdated instruments in its place of fixing it as soon as extra. The software program program moreover helps prioritize urgent duties.

It reveals which points need quick consideration, stopping small factors from turning into large, expensive breakdowns. A key benefit of using this software program program is improved instruments reliability.

Compliance with Regulatory Necessities

Reactive maintenance software program program helps companies observe commerce pointers. It retains detailed info of all maintenance work, making it easy to point compliance all through audits.

The software program program can ship alerts about required safety checks. It reminds workers to do these checks on time, serving to steer clear of fines for missed inspections.

Many industries have strict instruments safety pointers. The software program program tracks these pointers and helps assure they’re adopted. It might create research to point out compliance to inspectors.

Help for Sustainability Initiatives

Reactive maintenance software program program can help companies be further eco-friendly. It helps cut back waste by making instruments final extra. When machines work successfully, they use a lot much less energy.

The software program program can observe energy use and counsel strategies to boost it. It helps uncover instruments that’s using an extreme quantity of vitality, allowing companies to restore or change these energy hogs.

Digital twins and AI throughout the software program program can predict when parts will fail. This lets companies change parts on the correct time, stopping them from throwing away good parts too early or defending harmful ones too prolonged.

Conclusions and Future Outlook

Reactive maintenance software program program is able to play an vital perform in instruments repairs. It helps companies reply quickly to breakdowns and scale back downtime.

The software program program’s functionality to hint restore historic previous and costs gives firms helpful insights. This info can inform alternatives about when to modify ageing tools.

Artificial intelligence and machine learning are inclined to enhance reactive maintenance methods. These utilized sciences may predict failures sooner than they happen, mixing reactive and predictive approaches.

Mobile experience will make reactive maintenance further atmosphere pleasant. Technicians can entry restore knowledge and log work orders from anyplace.

Key future tendencies:

- Cloud-based choices for increased info sharing

- Integration with IoT sensors for real-time monitoring

- Augmented actuality devices to info repairs

- Automated scheduling and dispatch of technicians

As software program program maintenance evolves, reactive methods will become further proactive. They’ll help companies stability quick responses with strategic planning.

Firms that undertake superior reactive maintenance software program program will obtain a aggressive edge. They’ll cut back costs, extend instruments life, and improve operational effectivity.